Product Specification

| Specification Size | Model | Unit | AD-UF5-HR51 | AD-UF5-HR77 | |

| Average Pore Size | μm | 0.03 | 0.03 | ||

| Membrane Area | m² | 51 | 77 | ||

| Membrane Fiber Inner/Outer Diameter | mm | 0.7/1.3 | 0.7/1.3 | ||

| Effective Length of Membrane Fiber | mm | 1380 | 1880 | ||

| Installation Size and Method | - | Inlet, Outlet, and Concentrate Port DN50 | |||

| Side Inlet | Component Size (φ×H) | mm | φ225×1860 | φ225×2360 | |

| Inlet Type | - | PT3/8" Tapered Tube Internal Thread | |||

| Bottom Inlet | Component Size (φ×H) | mm | φ225×1900 | φ225×2400 | |

| Inlet Type | - | Component Inlet Pipe Connection Pagoda Connector | |||

| Weight | Tare Weight (including protective liquid) | kg | 45 | 60 | |

| Full Water Weight | kg | 80 | 100 | ||

| Material | Membrane Fiber Material | PVDF | |||

| Potting Glue | - | Epoxy Resin | |||

| Membrane Tube Material | - | UPVC | |||

| Maximum Inlet Turbidity | NTU | 300 | |||

| Maximum Inlet Pressure | MPa | 0.30 | |||

| Operating Conditions | Maximum Operating Temperature | ℃ | 40 | ||

| Tolerable pH Range | 2~12 | ||||

| Operating Mode | - | Crossflow or Dead-end Filtration | |||

[Note]: Other specifications of membrane products can be customized according to user needs.

Operating Conditions

| Operating Parameters Backwash Parameters Maintenance Cleaning (MC) In-situ Regenerative Cleaning (CIP) | Common Membrane Flux Range | HR:40~90L/(m² ·h) | |

| Transmembrane Pressure Range | 30~150kPa | ||

| Maximum Transmembrane Pressure During Filtration | 0.2MPa | ||

| Maximum Inlet Pressure | 0.3MPa | ||

| Maximum Inlet Turbidity | 300NTU | ||

| Crossflow Filtration Return Flow | 10%~30% | ||

| Maximum Particle Size | ≤300μm | ||

| Total Suspended Solids | ≤100mg/L | ||

| Operating Temperature | 1-40℃ | ||

| Backwashing Method | Air-Water Backwashing | ||

| Designed Backwashing Frequency | 24~48 times/day | ||

| Scrubbing Air Pressure During Backwashing | ≤150kPa | ||

| Backwash Flux | 0.5~1.5 times the permeate flux | ||

| Backwash Gas Flow Rate | 8~12Nm³/h(per unit) | ||

| Backwash Gas Source | Oil-free Compressed Air | ||

| Duration | 30~60s per cycle | ||

| Method 1 (Low Concentration In-situ Cleaning L-CIP) | Cleaning Method | Low concentration citric acid solution or sodium hypochlorite solution internal and external circulation cleaning | |

| Maintenance Cleaning Time | 50min (including rinsing time) | ||

| Citric Acid Frequency | 1 time / 1 ~ 3 days / set | ||

| Sodium Hypochlorite Frequency | 1 time/1~3 days/set | ||

| Cleaning Flow Rate | 1~2m³/membrane component | ||

| Maintenance Cleaning Chemical Concentration | 0.5%~1% citric acid 300~500ppm sodium hypochlorite | ||

| Method 2 (Chemical Study enhanced backwashing CEB) | Cleaning Method | Adding chemical agents to enhance backwashing during water backwashing | |

| Maintenance Cleaning Time | 15min | ||

| Citric Acid Frequency | 1 time/1~3 days/set | ||

| Sodium Hypochlorite Frequency | 1 time/1~3 days/set | ||

| Backwash flow rate | 0.5~1.5 times the permeate flux | ||

| Maintenance Cleaning Chemical Concentration | 0.5%~1% citric acid 300~500ppm sodium hypochlorite | ||

| CIP (Clean-in-Place) method | Alternating internal and external circulation cleaning with citric acid solution and sodium hypochlorite solution | ||

| CIP duration (acid washing or sodium hypochlorite washing) | 90~180min | ||

| CIP acid washing frequency | Once every 30~90 days per set | ||

| CIP sodium hypochlorite cleaning frequency | Once every 30~90 days per set | ||

| CIP circulation flow rate | 1~3m³/membrane module | ||

| Restorative cleaning solution concentration | 1%~2% citric acid 1000~3000ppm sodium hypochlorite | ||

| Optimal temperature range for each chemical cleaning solution | 20~30℃ | ||

| Heating temperature for each chemical cleaning solution | 20~30 | ||

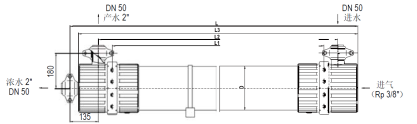

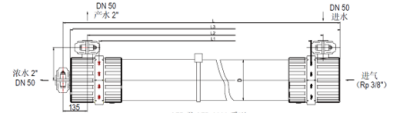

Size drawing

AD-UF5-HR51:

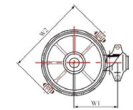

Unit | L | L1 | L2 | L3 | D | W1 | W2 |

mm | 1860 | 1500 | 1630 | 1820 | 225 | 180 | 342 |

AD-UF5-HR77:

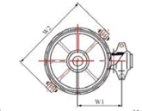

Unit | L | L1 | L2 | L3 | D | W1 | W2 |

mm | 2360 | 2000 | 2130 | 2320 | 225 | 180 | 342 |

Keywords

Send Query

Please leave your email and our professionals will contact you as soon as possible!

Pollution-resistant columnar membrane module

High Precision: Nominal pore size 0.03μm, uniform pore size, water turbidity <0.1NTU, SDI15 <2.5;

High Fouling Resistance: Special PVDF antioxidant modification, with better anti-pollution ability and good cleaning recovery rate;

High Strength: Good mechanical properties, breaking strength up to 5N;

High Applicability: Customized design to meet the replacement of components with different sizes and specifications in the market.

Contact Us

Classification:

Related Products