Specification

| Model | Average Permeability GPD(m3/d) | Average Desalination Rate % | Boron Removal Rate % | Membrane Area ft2(m2) | Feed Water Channel (mil) |

| AD-RO-SW4040-HR | 1450(5.5) | 99.8 | 90 | 85(8) | 28 |

| AD-RO-SW8040-HR(400) | 7000(26.5) | 99.82 | 90 | 400(37) | 34 |

| AD-RO-SW8040-HR(440) | 7700(29.1) | 99.82 | 90 | 440(41) | 28 |

| AD-RO-SW4040-HF | 1600(6.1) | 99.8 | 90 | 85(8) | 28 |

| AD-RO-SW8040-HF(400) | 9000(34) | 99.8 | 90 | 400(37) | 34 |

| AD-RO-SW8040-HF(440) | 9900(37.5) | 99.8 | 90 | 440(41) | 28 |

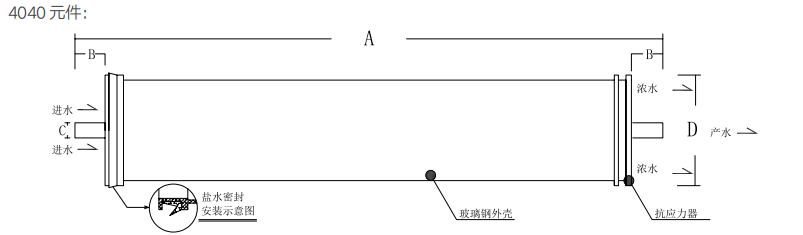

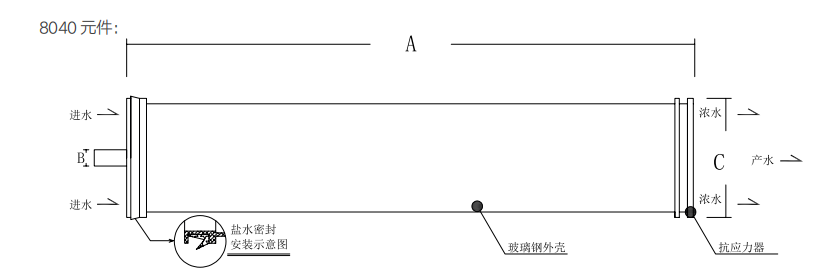

Size

| Element | A | B | C | D |

| 4040 | 40.0 (1016mm) | 1.05 (26.7mm) | 0.75(19mm) | 3.9 (99mm) |

| Element | A | B | C |

| 8040 | 40.0 (1016mm) | 1.125 (29mm) | 7.9 (201mm) |

Testing Conditions

Operating Pressure…………………………………800psi(5.52MPa)

Temperature………………………………………77 ℉(25℃)

Concentration………………………………………32000mg/LNaCl、5mg/L Boron

Single Membrane Element Recovery Rate………………………8%

pH…………………………………………7.5-8.0

Operating Limits

Precautions

① The product water should not be used one hour before the system is started for the first time;

② During startup and shutdown, excessive fluctuations in flow and pressure can pose a risk of membrane element rupture. The system should gradually increase/decrease pressure and flow during startup and shutdown operations, with a pressure rise/fall rate ≤ 0.07MPa/s;

③ The inlet SDI value must be below 5.0;

④ It is strictly prohibited for grease to enter the reverse osmosis system;

⑤ If the pressure on the product side is higher than the feed water pressure, it can cause physical damage to the membrane, so back pressure on the product side of the membrane element should be avoided at all times.

General Information

① Each membrane element is equipped with a concentrate sealing ring, a connection adapter, and corresponding O-rings at the time of shipment, specific content is subject to the actual product;

② Once the element is wetted, it should always be kept moist;

③ When the system is out of service for a long time, the membrane element should be immersed in a protective liquid to prevent microbial growth. The standard preservation liquid contains 1.0% (weight) sodium bisulfite (food grade) and 1.0% (weight) sodium citrate (food grade);

④ Users should avoid using any chemical agents that may affect the membrane element; if such chemical agents are used, Jiangsu Aidemans Technology Co., Ltd. will not bear warranty responsibilities;

⑤ Due to the inability to control the user's methods and conditions of use, Aidemans Company does not bear any consequences arising from the use of the information and data in this sample, nor does it guarantee the safety and applicability of the product, whether used alone or in conjunction with other products. Users are advised to conduct tests to determine its safety and suitability for their specific purposes;

⑥ Due to technical improvements and product updates, technical data may change at any time without prior notice.

Keywords

Send Query

Please leave your email and our professionals will contact you as soon as possible!

Reverse Osmosis SW

Contact Us

Classification:

Related Products