Product Specification

| Specification Size | Model | Unit | AD-UF3-HF51 | AD-UF3-HF77 | |

| Average Membrane Pore Size | μm | 0.03 | 0.03 | ||

| Membrane Area | m² | 51 | 77 | ||

| Membrane Fiber Inner/Outer Diameter | mm | 0.7/1.3 | 0.7/1.3 | ||

| Effective Length of Membrane Fiber | mm | 1380 | 1880 | ||

| Installation Size and Method | - | Feed Water, Product Water, Concentrated Water Port DN50 Copy Lin | |||

| Side Feed Water | Component dimensions (φ×H) | mm | φ225×1860 | φ225×2360 | |

| Inlet Form | - | PT3/8" Conical Pipe Internal Thread | |||

| Bottom Feed Water | Component dimensions (φ×H) | mm | φ225×1900 | φ225×2400 | |

| Inlet Port Form | - | Component Inlet Pipe Connection with Bell Joint | |||

| Weight | Empty Weight (including Quantitative Protective Liquid) | kg | 45 | 60 | |

| Full Water Weight | kg | 80 | 100 | ||

| Material | Membrane Fiber Material | PVDF | |||

| Potting Adhesive | - | Epoxy Resin | |||

| Membrane Tube Material | - | UPVC | |||

| Maximum Inlet Turbidity | NTU | 300 | |||

| Maximum Inlet Pressure | MPa | 0.30 | |||

| Operating Conditions | Maximum Operating Temperature | ℃ | 40 | ||

| Tolerable pH Range | 2~12 | ||||

| Operating Mode | - | Crossflow or Dead-end Filtration | |||

[Note]: Other specifications of membrane products can be customized according to user needs.

Operating Conditions

| Operating Parameters Backwash Parameters Maintenance Cleaning (MC) In-situ Recovery Cleaning (CIP) | Common Membrane Flux Range | HF:40~120L/(m² ·h) | |

| Transmembrane Pressure Range | 30~150kPa | ||

| Maximum Transmembrane Pressure During Filtration | 0.2MPa | ||

| Maximum Inlet Pressure | 0.3MPa | ||

| Maximum Inlet Turbidity | 300NTU | ||

| Crossflow Filtration Backflow Rate | 10%~30% | ||

| Maximum Particle Size | ≤300μm | ||

| Total Suspended Solids | ≤100mg/L | ||

| Working Temperature | 1-40℃ | ||

| Backwash Method | Air-Water Backwash | ||

| Design Backwash Frequency | 24~48 times/day | ||

| Scrubbing Air Pressure During Backwash | ≤150kPa | ||

| Backwash Flux | 0.5~1.5 times the product water flux | ||

| Backwash Gas Flow Rate | 8~12Nm³/h (per unit) | ||

| Backwash Gas Source | Oil-free Compressed Air | ||

| Duration | 30~60s per cycle | ||

| Method 1 (Low Concentration In-situ Cleaning L-CIP) | Cleaning Method | Low Concentration Citric Acid Solution or Sodium Hypochlorite Solution Internal and External Circulation Washing | |

| Maintenance Cleaning Occupied Time | 50min (including washing time) | ||

| Citric Acid Frequency | 1 time / 1 ~ 3 days / set | ||

| Sodium Hypochlorite Frequency | 1 time / 1~3 days / set | ||

| Washing Flow Rate | 1~2m³ per membrane component | ||

| Maintenance Cleaning Chemical Concentration | 0.5%~1% Citric Acid 300~500ppm Sodium Hypochlorite | ||

| Method 2 (Chemical Learn to strengthen backwashing CEB) | Cleaning Method | Add chemical agents to strengthen backwashing during water backwashing | |

| Maintenance Cleaning Occupied Time | 15min | ||

| Citric Acid Frequency | 1 time / 1~3 days / set | ||

| Sodium Hypochlorite Frequency | 1 time / 1~3 days / set | ||

| Backwash flow rate | 0.5~1.5 times the product water flux | ||

| Maintenance Cleaning Chemical Concentration | 0.5%~1% Citric Acid 300~500ppm Sodium Hypochlorite | ||

| Recovery cleaning (CIP) method | Alternating internal and external circulation rinsing with citric acid solution and sodium hypochlorite solution | ||

| CIP duration (acid cleaning or sodium hypochlorite cleaning) | 90~180min | ||

| CIP acid cleaning frequency | 1 time/30~90 days/set | ||

| CIP sodium hypochlorite cleaning frequency | 1 time/30~90 days/set | ||

| CIP circulation flow rate | 1~3m³/per membrane component | ||

| Concentration of recovery cleaning solution | 1%~2% citric acid 1000~3000ppm sodium hypochlorite | ||

| Optimal temperature range for each cleaning solution | 20~30℃ | ||

| Heating temperature for each cleaning solution | 20~30 | ||

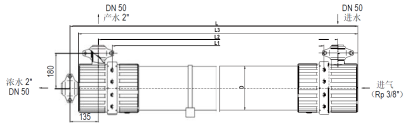

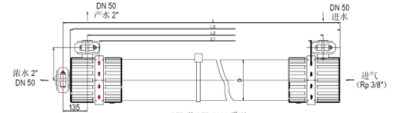

Size

AD-UF3-HF51:

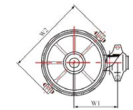

Unit | L | L1 | L2 | L3 | D | W1 | W2 |

mm | 1860 | 1500 | 1630 | 1820 | 225 | 180 | 342 |

AD-UF3-HF77:

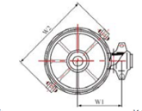

Unit | L | L1 | L2 | L3 | D | W1 | W2 |

mm | 2360 | 2000 | 2130 | 2320 | 225 | 180 | 342 |

Keywords

Send Query

Please leave your email and our professionals will contact you as soon as possible!

Ultrafiltration Membrane Module

High precision: nominal pore size of 0.03μm, uniform pore size, water turbidity < 0.1 NTU, SDI15 < 2.5; High flux: large channel component structure coupled with high flux membrane fibers, designed flux can reach 120 LMH; High water efficiency: precise fixed-length design, wastewater volume < 5%;

Contact Us

Classification:

Related Products